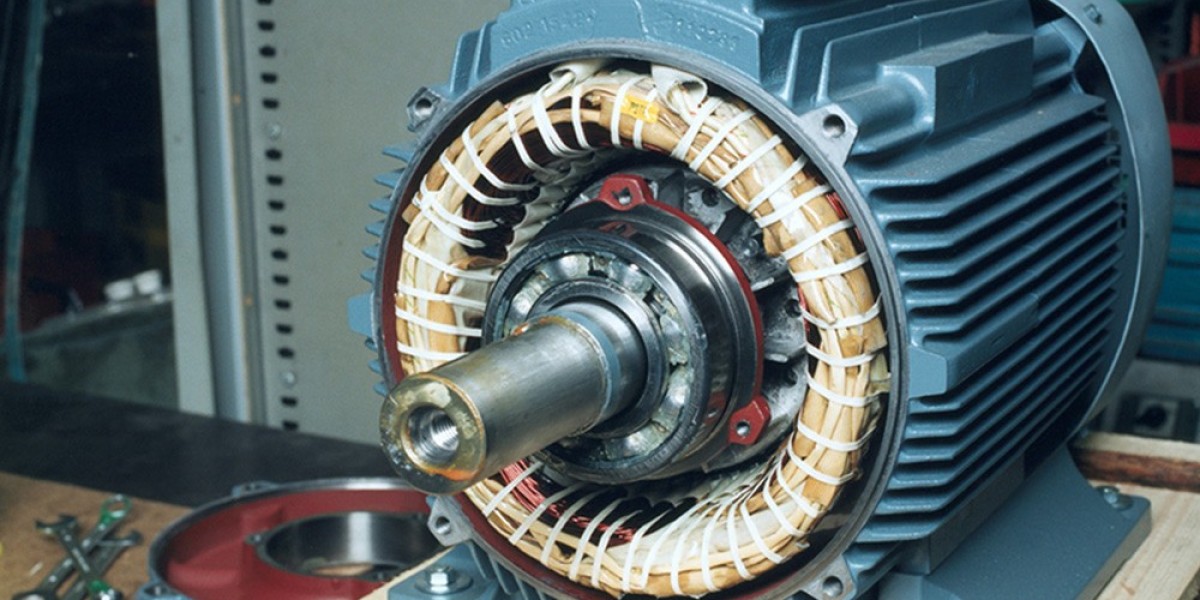

Motors convert electrical power into mechanical energy, called motive energy. They consist of stationary parts, the stator, and a spinning part, the rotor. The rotor contains wire windings on a soft iron, ferromagnetic core that respond to electric current to turn. To make the rotor spin continuously, its field magnet must be flipped at precisely the right time after each half turn of motion. This is done by the commutator.

Buy Electric Motors

Physicist Michael Faraday's experiments in 1821 with the rotation of a wire loop around a magnet set in motion by electric currents laid the foundation for the development of electric motors. Electric motors convert electrical power into mechanical energy to do work, and they're the opposite of generators, which perform the reverse function of converting mechanical energy into electricity.

A motor's rotating armature is made of one or more wire coils wrapped around a laminated, magnetically "soft" ferromagnetic core. When a current passes through the armature, it becomes a temporary magnet that interacts with a stationary magnetic field produced by either permanent magnets (PMs) or another winding in the rotor. The interaction creates a force that rotates the shaft. The commutator, which is a rotary buy electric motors switch, continually switches power to the armature's windings as the rotor turns.

Motor efficiency is determined by how much of the original electrical input energy is converted to motive energy during the conversion process. Motor losses, which include friction in the bearings and other mechanical components and waste heat from a motor's operation, add up to a significant amount of power loss. Two of the most important determinants for saving energy are selecting the correct motor size and using smart motor control technologies that reduce electrical consumption by adjusting speed or torque to match load demands.

Used Electric Motors

Electric motors convert electrical power into rotation and other forms of mechanical energy. They use force generated by the interaction between winding direct (DC) or alternating current electricity and magnetic fields to rotate the shaft and drive the mechanical load. In the process, some of the electrical energy changes to heat energy and is lost, which reduces efficiency and lifespan.

Fleming’s left-hand rule dictates that an upward force directed from the north pole of a magnet toward the south pole creates a torque that pulls on the rotor and causes it to spin. To keep the force directed in a constant direction and to manage the speed of the motor, brushes and a commutator reverse the current flow each time the shaft makes a half-turn. buy electric motor from surplusrecord industrial electrical motors are the best buy of electric motor used electric motor for sale at surplusrecord. surplus motor are the best Brushless DC motors (BLDC) avoid the need for a commutator and brushes, which can cause electrical and RF noise. They have multiple taps on the field coil that allow for stepped output speeds. Household blenders, for example, utilize these motors. BLDC motors also tend to have elevated mechanical fins that further dissipate the heat created in the many coils due to resistance.

Ironless BLDC motors have an advantage over other iron-rotor DC motors in that they eliminate cogging, which occurs when the attraction between the rotor iron and the magnetic field varies during operation. They also have a higher switching frequency, allowing for more precise speed control and enabling a lower voltage standard.

Surplus Motors

Induction motors use the principles of electromagnetic induction to produce current in a rotating rotor. A varying magnetic field induces current in an insulated iron core lamina inside the rotor, which generates torque and rotation. This kind of electric motor doesn’t require permanent magnets, commutator rings or brushes, so it is self-starting and requires a power source only to operate once it is started.

These kinds of motors are usually used in fans, pumps and conveyors, but they can also be used to drive cranes and machine tools. These machines are very durable and can be used to meet the demands of a wide range of industrial applications.

Buying a surplus electric motor can be the best solution for your business, especially when you need to replace an existing model that is no longer being manufactured. A surplus model is also a great option for those looking to save on the cost of a new model without sacrificing reliability and warranties.

At Steven Levy Enterprises, we sell a variety of surplus Baldor, US Electric, Leeson, Reliance and GE motors, including three-phase, single-phase, DC motors and more. All of our surplus electric motors are reconditioned and tested before they are available for sale. This ensures that your new motor will be ready for installation right away, and it also guarantees a warranty that is equal to or exceeds the manufacturer’s original warranty.

Industrial Electric Motors

Electric motors convert electrical energy into linear or rotary force (torque) to power equipment and machinery. They can be powered by DC current from batteries, but most industrial motors are energized from AC sources like the power grid or generators.

Industrial electric motors can be single- or three-phase. Single-phase motors are commonly used in residential and small commercial applications, while three-phase motors power larger HVAC systems and manufacturing equipment.

Most industrial electric motors are AC induction motors that use electromagnetism to spin a rotor inside the stationary stator. Several varieties exist, including squirrel cage and wound rotor motors. AC induction motors are robust, inexpensive, and efficient, but they cannot operate at very high speeds.

The rotor consists of wire coils wrapped around a laminated, magnetically soft ferromagnetic core. Current from brushes flows through one of the armature windings, making it a temporary magnet that interacts with the magnetic field from permanent magnets (PMs) or another armature winding in the stator to produce rotational motion. An insulated gap allows the rotor to spin while remaining in contact with the stator, which reduces eddy current losses.

Industrial electric motors can be single- or 3-phase, brushed or brushless, with various frame sizes and shaft configurations. They can be air- or liquid-cooled, and they can run on AC or DC current. Most industrial electric motors are regulated by nationally and internationally harmonised efficiency levels, which are set on the Energy Performance Ladder.

Search

Popular Posts