African Valve is a leading Triple Offset Butterfly Valve supplier in South Africa.A Triple Offset Butterfly Valve is a type of butterfly valve that incorporates three offsets to achieve a reliable sealing mechanism and precise control of fluid flow. The three offsets refer to three distinct characteristics of the valve design. First, the valve's shaft is offset from the centerline of the disc, allowing for a more effective sealing contact between the disc and the seat. Second, the center of rotation of the disc is offset from the centerline of the piping system, which helps to reduce wear and friction during operation.

Finally, the cone shape of the sealing surface is offset from the centerline of the valve, enabling a cam-like, metal-to-metal sealing contact. These three offsets work together to provide a bubble-tight shut-off, minimal seat wear, and precise flow control, making triple offset butterfly valves suitable for a wide range of applications.Triple offset butterfly valves are commonly used in industries such as oil and gas, petrochemicals, power generation, and water treatment. They are particularly favored in applications where tight shut-off is crucial, such as in high-pressure, high-temperature, and abrasive media conditions. African valve is the best Triple offset butterfly valve supplier in South Africa.Triple offset butterfly valves are also employed in processes that require throttling or modulating control, thanks to their ability to provide accurate flow regulation.

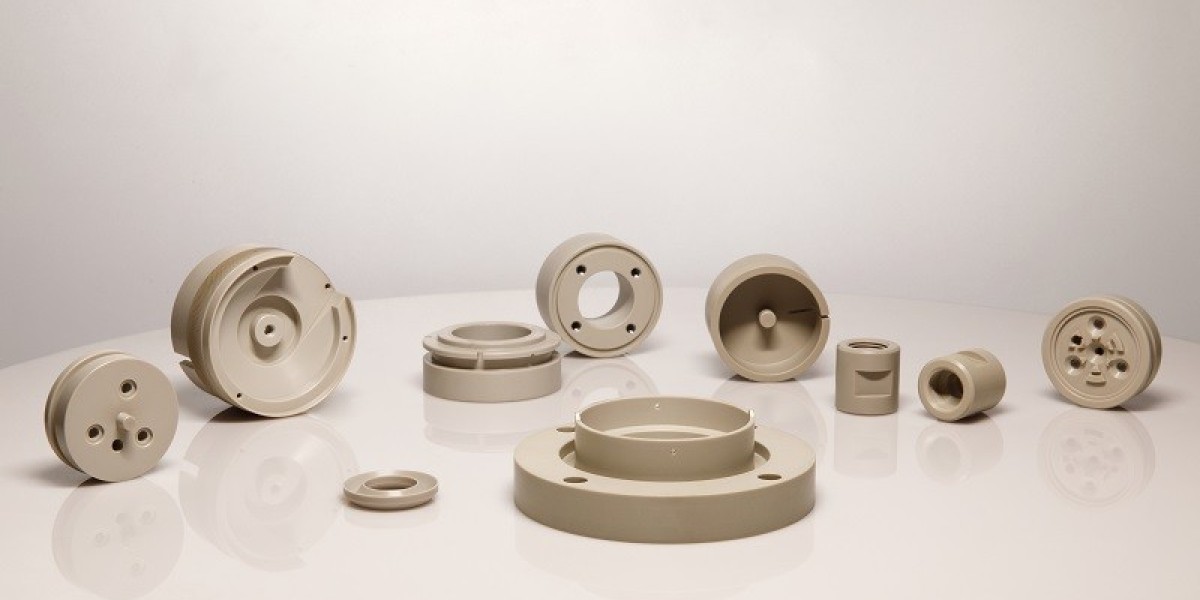

Parts:

- Body

- Disc

- Shaft

- Actuator

Advantages:

- Excellent Sealing Performance: Triple offset butterfly valves provide a bubble-tight shut-off due to the unique triple offset design. The offset shaft, disc, and sealing cone create a cam-like, metal-to-metal sealing contact, minimizing leakage and ensuring reliable sealing even in high-pressure and high-temperature applications.

- Low Friction and Wear: The triple offset design reduces friction and wear between the disc and seat during valve operation. The offset rotation center and cone shape of the sealing surface allow for a smooth and precise opening and closing action, resulting in minimal wear on the sealing components.

- High Flow Capacity: Triple offset butterfly valves are known for their high flow capacity. The disc's streamlined shape and central flow channel minimize pressure drop and turbulence, allowing for efficient fluid flow with reduced energy consumption.

- Versatile Applications: These valves are suitable for a wide range of applications across industries. They can handle various fluids, including corrosive and abrasive media. Triple offset butterfly valves are commonly used in oil and gas, petrochemicals, power generation, water treatment, chemical processing, and other industrial applications.

- Extended Service Life: The materials used in triple offset butterfly valves, such as stainless steel or exotic alloys, provide excellent resistance to corrosion, erosion, and wear. This, combined with their robust construction and reliable sealing, results in an extended service life and reduced maintenance requirements.

Applications:

- Oil and Gas Industry: Triple offset butterfly valves are widely used in the oil and gas industry, particularly in pipelines, tank farms, and process units. They are suitable for applications involving crude oil, natural gas, refined products, and various petrochemical processes.

- Power Generation: These valves find applications in power plants, including thermal power plants and combined cycle plants. They are utilized in cooling water systems, boiler feedwater systems, steam systems, and other power generation processes.

- Water Treatment: Triple offset butterfly valves are employed in water treatment plants for controlling the flow of water, wastewater, and various chemicals. They are used in applications such as pumping stations, distribution networks, and treatment processes.

- Chemical Processing: Triple offset butterfly valves are utilized in the chemical industry for handling aggressive chemicals, acids, and corrosive fluids. They are employed in processes such as chemical production, refining, and petrochemical manufacturing.

- Process Industries: These valves have applications in various process industries, including pulp and paper, mining. They provide reliable shut-off and precise control in different fluid handling processes.

Description:

- Material : Cast iron, Ductile iron, Stainless steel (SS304, SS316, F304, F316, CF8, CF8M, SS316L, SS409L), Carbon steel, Duplex steel.

- Class : PN10 to PN100, ANSI 150 to 600

- End Connection: Wafer , Lug, Flanged

- Size: 2″ to 72”

- Operation: Handwheel, Gear Operated, Electric Actuated, Pneumatic Actuated

Visit our website to know more:

https://www.africanvalve.com/product-category/triple-offset-butterfly-valve/